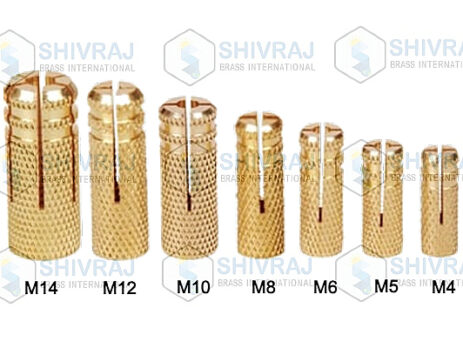

How to Install Brass Anchors – Drop in Anchors inside Concrete surface? Step-by-step Guide

Brass anchors - drop in anchors are a part of fasteners used to fix bolts, screws or fixtures to a concrete surface or a brick in construction industry. The knurled surface of the brass drop in anchors provide solid grip and resist rotation inside the hole so that the bolt or fixtures remains at a stable position. The expansion of the brass anchors occurs with the force through tightening of the bolt. Brass anchors are inexpensive and no special...

Brass CNC Machining Parts for Auto Parts Assembly

Brass CNC Machining Parts are the need of the hour as the world is becoming more competitive with increasing demand for precision components with parameter like zero defect parts, mass production of high quality parts, reduced lead time, competitive pricing, minimum wastage of raw materials, improved production efficiency and total human safety. Machines like CNC and VMC are mainly used for production of Brass Precision Turned Components. Software like CAD - Computer Aided Design, CAM - Computer Aided Manufacturing are used...

About Stainless Steel Precision turned Components – CNC Turned Stainless Steel Parts

Stainless Steel Precision Turned Components are the need of the hour as the world is becoming more competitive with increasing demand for precision components with parameter like zero defect parts, mass production of high quality parts, reduced lead time, competitive pricing, minimum wastage of raw materials, improved production efficiency and total human safety. Machines like CNC and VMC are mainly used for production of Stainless Steel Precision Turned Parts. Software like CAD - Computer Aided Design, CAM - Computer Aided...

About Brass Hydraulic Parts – Brass Precision Turned Components

Brass Precision Turned Components are the need of the hour as the world is becoming more competitive with increasing demand for precision components with parameter like zero defect parts, mass production of high quality parts, reduced lead time, competitive pricing, minimum wastage of raw materials, improved production efficiency and total human safety. Machines like CNC and VMC are mainly used for production of Brass Precision Turned Parts. Software like CAD - Computer Aided Design, CAM - Computer Aided Manufacturing are...

About Copper Bolts | Copper Fasteners

Bolts are types of fasteners used to connect two objects like metal, plastic, rubber, wood, etc in a fixed position. They are often used with a nut for tightening two objects. Bolt consist of cylindrical body with external threads and a head above the body. The external threads pairs with the internal threads of the nut providing tight positioning between the two objects. Also they help in assembling and disassembling the two objects. Bolts consist of different shapes, size, materials...

About Brass Locknut, Stainless Steel Locknut and Aluminium Locknut

Lock nuts are a type of fasteners that are used to overcome resistance due to torque and vibrations in components. To prevent loosening of the bolted joint due to vibrations, apart from jam nut, lock washers and thread locking fluid, locknut play an important role to prevent vibration. Types: Lock nut, Self locking nut, Locking nut, Stiff nut, Elastic stop nut. Applications: Brass Locknuts, Stainless steel locknuts and Aluminium locknuts are used in various applications like Cable Gland accessories, Pipe fittings, Compression...

5 Advantages of using Precision Turned Components in the Industries

Precision Turned Components are the need of the hour as the world is becoming more competitive with increasing demand for precision components with parameter like zero defect parts, mass production of high quality parts, reduced lead time, competitive pricing, minimum wastage of raw materials, improved production efficiency and total human safety. Machines like CNC and VMC are mainly used for production of Precision Turned Parts. Software like CAD - Computer Aided Design, CAM - Computer Aided Manufacturing are used for...

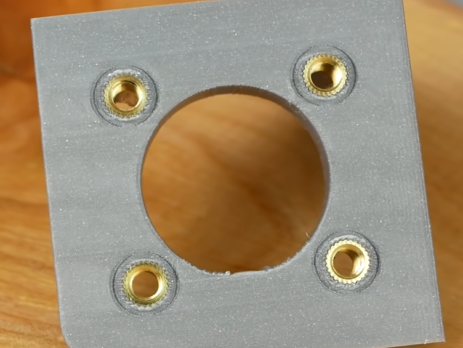

How to Install Brass Threaded Inserts for Plastic Injection Molding? Step-by-step Guide

Brass Threaded Inserts are part of fasteners used to easily assemble and disassemble materials like wood, plastic, aluminium, rubber, etc. without causing any damage to components and thus improve their reusability. Brass Threaded Insert Molding process can be carried out with the plastic molding materials like Thermoplastics, Thermosets, Elastomers. This process is also known as Thermal installation process of brass threaded inserts. Among various sizes, m3 threaded inserts are widely used. Here we are going to discuss step-by-step method to install...

Content is Copy Protected

Content is Copy Protected